Iimveliso

Umcu wentsimbi ogxunyekiweyo we-PE umbhobho wegesi

Isicelo

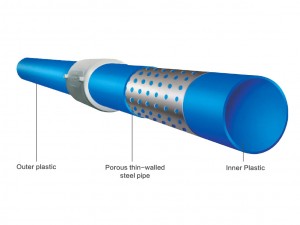

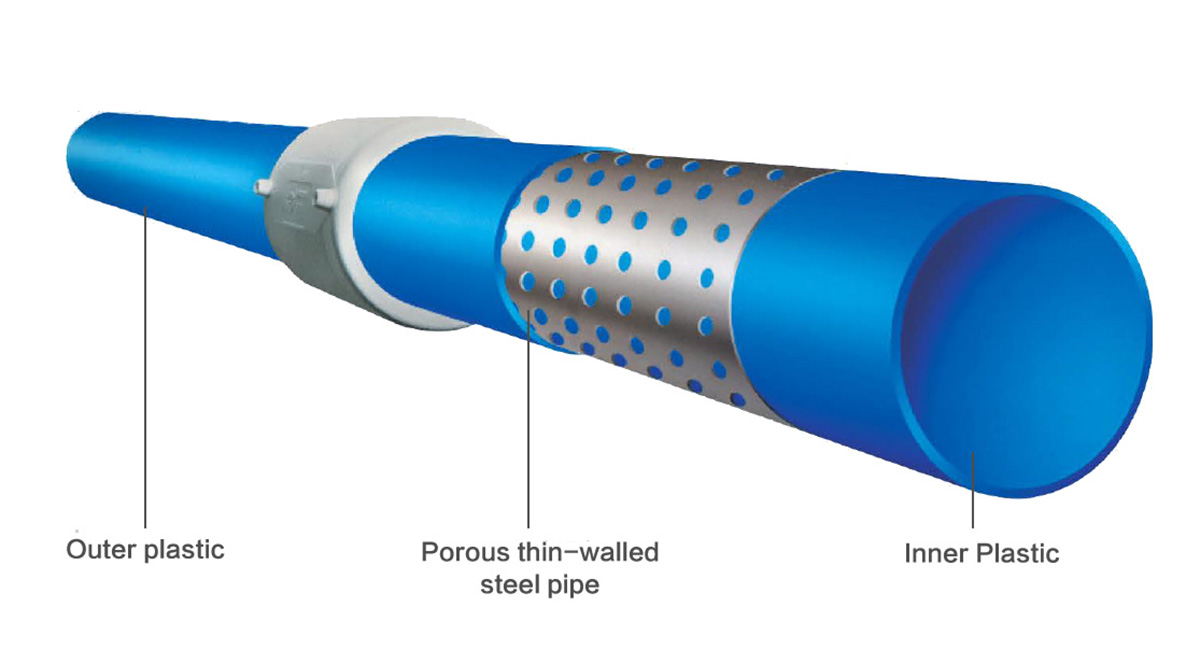

Umbhobho odibeneyo wentsimbi we-polyethylene owenziweyo wenziwa ngentsimbi epholileyo eqengqelekayo kunye ne-thermoplastics njengemathiriyeli ekrwada, kunye nemibhobho yentsimbi enodonga olubhityileyo eyenziwe yi-argon ye-arc butt welding okanye i-plasma spiral welding isetyenziswa njengezomeleza. Iileya zangaphandle kunye nezangaphakathi ziyi-thermoplastics edibeneyo emacala amabini. Uhlobo olutsha lombhobho woxinzelelo oludibeneyo, ngenxa yokuba i-porous-ebiyelwe ngentsimbi yokuqiniswa kombhobho wentsimbi esongelwe kwi-thermoplastic eqhubekayo, lo mbhobho odibeneyo awupheleli nje kuphela kwiintsilelo ezichaphazelekayo zemibhobho yentsimbi kunye nemibhobho yeplastiki, kodwa inobungqongqo bemibhobho yentsimbi kunye nokugqwala. ukumelana nemibhobho yeplastiki. Sisisombululo sepetroleum kunye namashishini amachiza. Ngumbhobho ofunekayo ngokungxamisekileyo wemibhobho emikhulu kunye nobude obuphakathi eqinile kwimimandla yamayeza, ukutya, imigodi, igesi kunye nezinye iindawo. Ikwayimpumelelo yenguqu epheleleyo yobuchwepheshe ukusombulula umbhobho ongundoqo wokwakha kunye nonikezelo lwamanzi lukamasipala. Luhlobo olutsha lombhobho odibeneyo kwi-21stkwinkulungwane.

Iimbonakalo

Ukusebenza okucocekileyo

Isalathiso sococeko kunye nokhuseleko lombhobho owenziwe ngentsimbi yentsimbi enemingxuma yeplastiki ihlangabezana neemfuno ze-GB9687 "uMgangatho woBucoceko wePolyethylene yeeMveliso ezibunjiweyo zokuPakisha ukutya" kunye ne-GВ/Т17219 "Umgangatho woVavanyo loKhuseleko lweZixhobo zokusasazwa kwamanzi okusela kunye neZixhobo kunye neZixhobo zoKhuseleko". Yeyona ndawo ithatha indawo yombhobho ofakwe igalvanized kunye nombhobho owenziwe ngentsimbi.

Udonga lwangaphakathi olugudileyo kunye nokusebenza kokujikeleza

Udonga lwangaphakathi lwebhanti yentsimbi yentsimbi yombhobho weplastiki edibeneyo igudileyo kakhulu, kwaye uburhabaxa obupheleleyo yi-1/20 kuphela yombhobho wentsimbi. Umthamo wokuhambisa phantsi kweemeko ezifanayo malunga ne-30% ephezulu kunombhobho wensimbi.

IiParameters zobuGcisa

| Ubungakanani benkcazo, ukutenxa kunye noxinzelelo oluncinci: ukuhlangabezana neemfuno zoMphathiswa womgangatho wokwakha CJ/T181-2003 | |||||

| Idayamitha yangaphandle yegama kunye nokutenxa | Ubukhulu bodonga lwegama kunye nokutenxa | Ngaphandle kokujikeleza | Uxinzelelo lwegama | Ubuncinci bexabiso lika-S | Ubude kunye nokutenxa |

| Dn(mm) | En(mm) | Mm | Mpa | Mm | mm |

| 50+0.5 0 | 4.0+0.5 9 | 1.0 | 1.0 | 1.5 | 6000+20 0 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5+0.6 0 | 1.26 | 1.0 | 1.5 | |

| 75+0.7 0 | 5.0+0.7 0 | 1.5 | 1.0 | 1.5 | |

| 90+0.9 0 | 5.5+0.8 0 | 1.8 | 1.0 | 1.5 | |

| 110+1.0 0 | 6.0+0.9 0 | 2.2 | 1.0 | 1.5 | |

| 140+1.1 0 | 8.0+1.0 0 | 2.8 | 1.0 | 2.5 | |

| 160+1.2 0 | 10.0+1.1 0 | 3.2 | 1.0 | 2.5 | |

| 200+1.3 0 | 11.0+1.2 0 | 4.0 | 1.0 | 2.5 | |

| 250+1.4 0 | 12.0+1.3 0 | 5.0 | 0.8 | 3.5 | |

| 315+1.6 0 | 13.0+1.4 0 | 6.3 | 0.8 | 3.5 | |

| 400+1.6 0 | 15.0+1.5 0 | 8.0 | 0.8 | 3.5 | |

| 500+1.7 0 | 16.0+1.6 0 | 10.0 | 0.6 | 4.0 | |

| 630+1.8 0 | 17.0+1.7 0 | 12.3 | 0.6 | 4.0 | |

| Qaphela: Uxinzelelo oluncinci lombhobho odibeneyo luxinzelelo oluphezulu oluvunyelwe ukuba umbhobho uthuthe amanzi kwi-20 ° С. Ukuba iqondo lokushisa liyatshintsha, uxinzelelo olusebenzayo kufuneka lulungiswe ngokwe-coefficient yoxinzelelo lobushushu bezinto ezahlukeneyo. Ixabiso le-S: umgama ukusuka kububanzi bangaphandle bokuqiniswa ukuya kwindawo yangaphandle yombhobho. | |||||

| Iimfuno zokusebenza komzimba kunye noomatshini | ||

| Iprojekthi | Ukusebenza | |

| Ukuqina kweringi, KN/m2 | >8 | |

| Ukuncipha kwexesha elide (110 ° С, gcina i-1h) | <0.3% | |

| Uvavanyo lwe-hydraulic | Ubushushu: 20 ° С; Ixesha: 1h; Uxinzelelo lwegama x2 | Ayophukanga |

| Ubushushu: 80 ° С; Ixesha: 165h; Uxinzelelo: Uxinzelelo lwegama x2x0.71 (into yokunciphisa) | ||

| Uvavanyo loxinzelelo lwe-Burst | Ubushushu: 20 ° С, ukuqhuma uxinzelelo≥uxinzelelo oluqhelekileyo x3.0 | Ukuqhushumba |

| Ixesha lokungeniswa kwe-oxidation (200 ° С), min | >20 | |

| Ukumelana nokwandiswa koxinzelelo olukhawulezayo (80 ° С, 4.0Mpa) / h | >1000 | |

| Ukumelana nemozulu (emva kokuba umbhobho ufumene≥3.5GJ/m2ukuguga amandla) | Ukuhlangabezana neemfuno zezinto ze-2,3 kunye ne-4 kule theyibhile, kwaye unokugcina ukusebenza kakuhle kwe-welding | |