Iimveliso

Umcu wentsimbi ye-Peforated umbhobho we-PE Ukumelana nobushushu

Isicelo

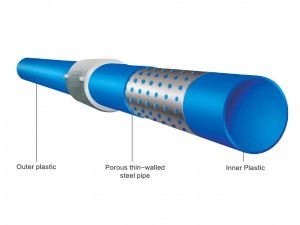

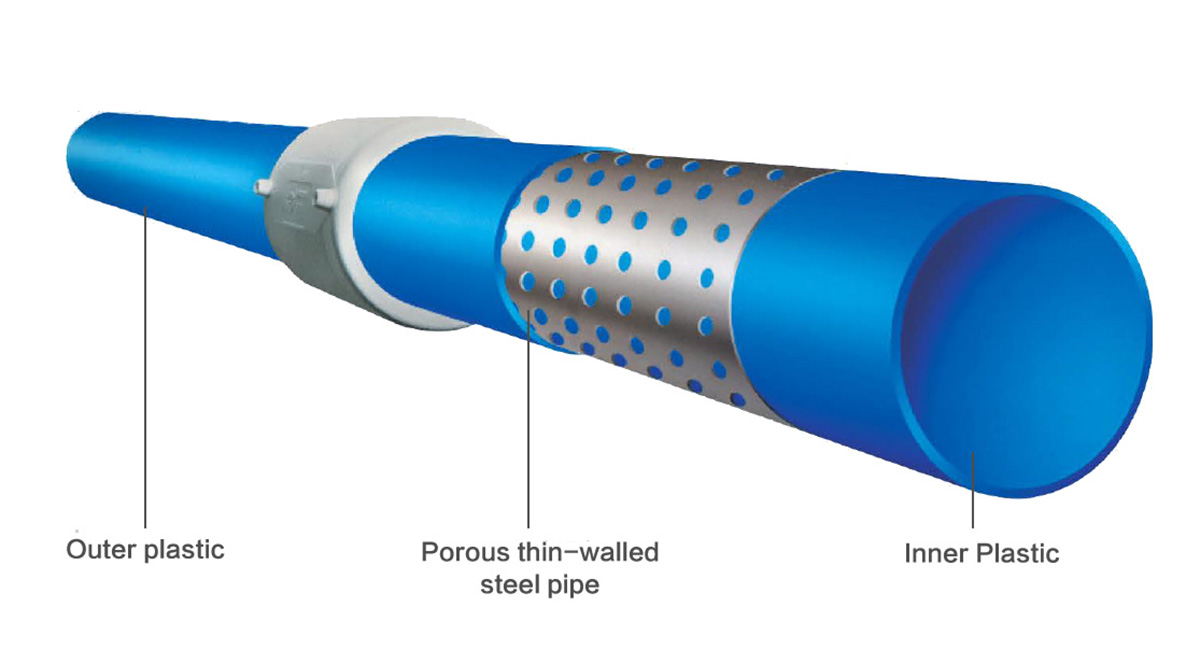

Umbhobho odibeneyo wentsimbi we-polyethylene owenziweyo wenziwa ngentsimbi epholileyo eqengqelekayo kunye ne-thermoplastics njengemathiriyeli ekrwada, kunye nemibhobho yentsimbi enodonga olubhityileyo eyenziwe yi-argon ye-arc butt welding okanye i-plasma spiral welding isetyenziswa njengezomeleza. Iileya zangaphandle kunye nezangaphakathi ziyi-thermoplastics edibeneyo emacala amabini. Uhlobo olutsha lombhobho woxinzelelo oludibeneyo, ngenxa yokuba i-porous-ebiyelwe ngentsimbi yokuqiniswa kombhobho wentsimbi esongelwe kwi-thermoplastic eqhubekayo, lo mbhobho odibeneyo awupheleli nje kuphela kwiintsilelo ezichaphazelekayo zemibhobho yentsimbi kunye nemibhobho yeplastiki, kodwa inobungqongqo bemibhobho yentsimbi kunye nokugqwala. ukumelana nemibhobho yeplastiki. Sisisombululo sepetroleum kunye namashishini amachiza. Ngumbhobho ofunekayo ngokungxamisekileyo wemibhobho emikhulu kunye nobude obuphakathi eqinile kwimimandla yamayeza, ukutya, imigodi, igesi kunye nezinye iindawo. Ikwayimpumelelo yenguqu epheleleyo yobuchwepheshe ukusombulula umbhobho ongundoqo wokwakha kunye nonikezelo lwamanzi lukamasipala. Luhlobo olutsha lombhobho odibeneyo kwi-21stkwinkulungwane.

Iimbonakalo

Ukuqina komsesane ophezulu kunye nokuqina okuphezulu

Umbhobho weplastiki owenziwe ngentsimbi enemingxuma unokuqina komsesane ophezulu kunye nokuqina okuphezulu kufutshane nemibhobho yesinyithi, kwaye ifaneleke ngakumbi ukubekwa ngaphezulu kweepaseji zemibhobho.

Ukusebenza kokhuseleko

Isakhelo esomeleziweyo sombhobho odibeneyo webhanti yentsimbi yentsimbi kunye nezixhobo zeplastiki ekrwada ziqulathwe ngokupheleleyo ngokutyhubela umnatha onemingxuma, kwaye kukho inkxalabo yokuxobula iplastiki yodonga lwangaphakathi nangaphandle kunye nesakhelo sentsimbi. Uxhulumaniso lokudibanisa umbane lunokumelana okuqinileyo kumzobo we-axial, kwaye inkqubo yepayipi inokuthembeka okuphezulu. Kwiimeko eziqhelekileyo, ubomi benkonzo bufikelela kwiminyaka engama-50.

IiParameters zobuGcisa

| Idayamitha yangaphandle yegama kunye nokutenxa | Ubukhulu bodonga lwegama kunye nokutenxa | Uxinzelelo lwegama | Ubuncinci bexabiso lika-S |

| Dn(mm) | En(mm) | Mpa | Mm |

| 50+0.5 0 | 6.0+1.5 9 | 2.0 | 1.5 |

| 63+0.6 0 | 6.5+1.5 0 | 2.0 | 1.5 |

| 75+0.7 0 | 7.0+1.5 0 | 2.0 | 1.5 |

| 90+0.9 0 | 8.0+1.5 0 | 2.0 | 1.5 |

| 110+1.0 0 | 9.0+1.5 0 | 2.0 | 1.5 |

| 140+1.1 0 | 9.0+1.5 0 | 1.6 | 2.0 |

| 160+1.2 0 | 10.0+1.8 0 | 1.6 | 2.0 |

| 200+1.3 0 | 11.0+2.0 0 | 1.6 | 2.0 |

| 225+1.4 0 | 11.5+2.2 0 | 1.6 | 2.0 |

| 250+1.4 0 | 12.0+2.2 0 | 1.6 | 2.0 |

| 280+1.5 0 | 12.5+2.3 0 | 1.6 | 2.5 |

| 315+1.5 0 | 13.0+2.5 0 | 1.25 | 2.5 |

| 355+1.6 0 | 14.0+2.5 0 | 1.25 | 2.5 |

| 400+1.6 0 | 15.0+2.8 0 | 1.25 | 2.5 |

| 450+1.8 0 | 15.0+2.8 0 | 1.25 | 2.5 |

| 500+2.0 0 | 16.0+3.0 0 | 1.25 | 2.5 |

| Iimpawu ezibonakalayo zombhobho odibeneyo | ||

| Iprojekthi | Imfuneko yokusebenza | |

| Ukuqhaqha ukuzinza phantsi koxinzelelo | Akukho zintanda | |

| Umyinge wokuncipha kwexesha elide (110 ° С, gcina i-1h) | <0.3% | |

| Uvavanyo lwe-hydraulic | Ubushushu: 20 ° С; Ixesha: 1h; Uxinzelelo: uxinzelelo lwegama x1.5 | Ayophukanga Akukho kuvuza |

| Ubushushu: 70 ° С; Ixesha: 165h; Uxinzelelo: Uxinzelelo lwegama x1.5x0.76 | ||

| Ubushushu: 85 ° С; Ixesha: 165h; Uxinzelelo lokuqhuma ≥ uxinzelelo lwegama x1.5x0.66 | ||