Iimveliso

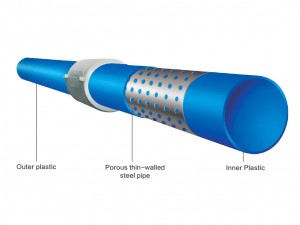

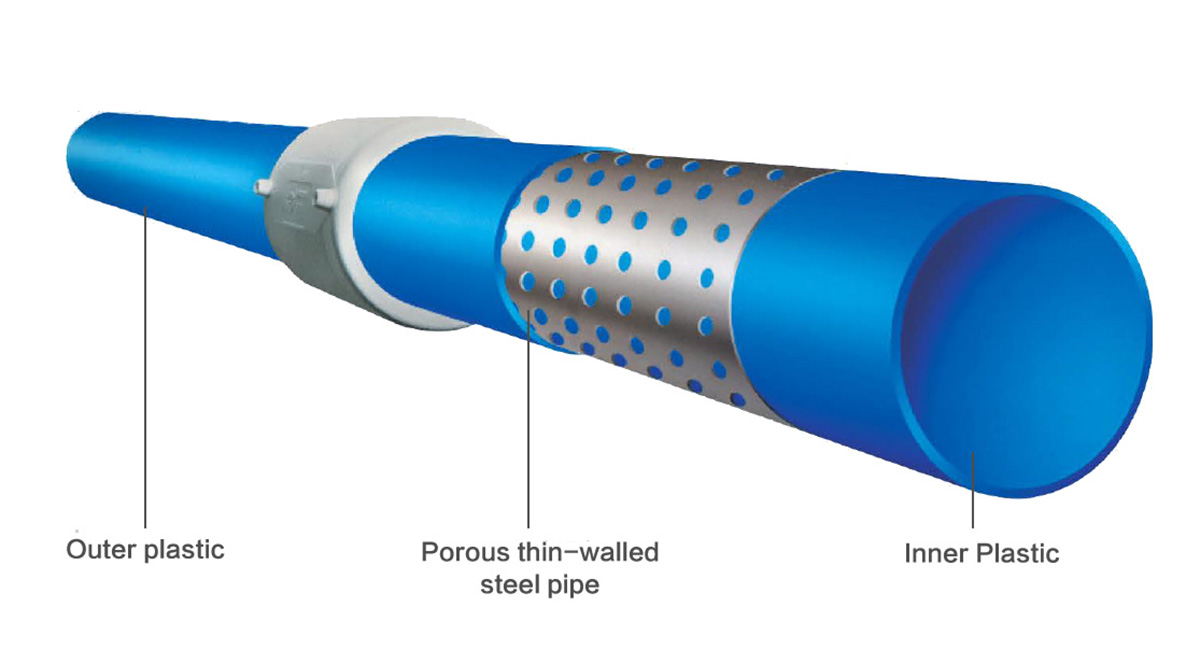

Umcu wentsimbi egqobhoziweyo Umbhobho we-PE Ukubonelela ngamanzi

Isicelo

Umbhobho odibeneyo wentsimbi we-polyethylene owenziweyo wenziwa ngentsimbi epholileyo eqengqelekayo kunye ne-thermoplastics njengemathiriyeli ekrwada, kunye nemibhobho yentsimbi enodonga olubhityileyo eyenziwe yi-argon ye-arc butt welding okanye i-plasma spiral welding isetyenziswa njengezomeleza. Iileya zangaphandle kunye nezangaphakathi ziyi-thermoplastics edibeneyo emacala amabini. Uhlobo olutsha lombhobho woxinzelelo oludibeneyo, ngenxa yokuba i-porous-ebiyelwe ngentsimbi yokuqiniswa kombhobho wentsimbi esongelwe kwi-thermoplastic eqhubekayo, lo mbhobho odibeneyo awupheleli nje kuphela kwiintsilelo ezichaphazelekayo zemibhobho yentsimbi kunye nemibhobho yeplastiki, kodwa inobungqongqo bemibhobho yentsimbi kunye nokugqwala. ukumelana nemibhobho yeplastiki. Sisisombululo sepetroleum kunye namashishini amachiza. Ngumbhobho ofunekayo ngokungxamisekileyo wemibhobho emikhulu kunye nobude obuphakathi eqinile kwimimandla yamayeza, ukutya, imigodi, igesi kunye nezinye iindawo. Ikwayimpumelelo yenguqu epheleleyo yobuchwepheshe ukusombulula umbhobho ongundoqo wokwakha kunye nonikezelo lwamanzi lukamasipala. Luhlobo olutsha lombhobho odibeneyo kwi-21stkwinkulungwane.

Iimbonakalo

Amandla aphezulu kunye nokwandiswa komgca ophantsi.

Ngenxa yokomelezwa kwesakhelo sentsimbi, i-perforated steel strip yeplastiki yombhobho odibeneyo unamandla aphezulu, ukuqina okuphezulu kunye nokuchasana kwempembelelo kunombhobho weplastiki. Ngelo xesha, umphumo wokunqanda kwesakhelo sensimbi uphinde wenze i-perforated steel strip yeplastiki ipayipi edibeneyo ibe nomgca ophantsi ofana nombhobho wensimbi. Ukwandiswa komlinganiso kunye nokumelana no-сгеер.

Ukonakala kunye nokumelana nokunxiba.

I-high-density polyethylene material ekhethiweyo kwi-perforated steel strip yeplastiki ipayipi yeplastiki yi-crystalline non-polar impahla yepolymer eneempawu ezizinzileyo zeekhemikhali, ukuchasana ne-asidi eninzi, iityuwa ze-alkali kunye ne-organic media, kunye ne-electrochemical corrosion. Ukusebenza kokugaya kumaxesha angama-5 aphezulu kunemibhobho yensimbi.

IiParameters zobuGcisa

Le mveliso isebenzisa i-polyethylene resin ekhethekileyo, kunye neempawu zayo zomzimba kunye nezomatshini zidibana noMphathiswa wokwakha umgangatho we-CJ/T181-2003 kunye nomgangatho woshishino lweekhemikhali HG/T3706-2014.

| Ubungakanani benkcazo, ukutenxa kunye noxinzelelo oluncinci: ukuhlangabezana neemfuno zoMphathiswa womgangatho wokwakha CJ/T181-2003 | |||||

| Idayamitha yangaphandle yegama kunye nokutenxa | Ubukhulu bodonga lwegama kunye nokutenxa | Ngaphandle kokujikeleza | Uxinzelelo lwegama | Ubuncinci bexabiso lika-S | Ubude kunye nokutenxa |

| Dn(mm) | En(mm) | Mm | Mpa | Mm | mm |

| 50+0.5 0 | 4.0+0.5 9 | 1.0 | 2.0 | 1.5 | 6000+20 0 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5+0.6 0 | 1.26 | 2.0 | 1.5 | |

| 75+0.7 0 | 5.0+0.7 0 | 1.5 | 2.0 | 1.5 | |

| 90+0.9 0 | 5.5+0.8 0 | 1.8 | 2.0 | 1.5 | |

| 110+1.0 0 | 6.0+0.9 0 | 2.2 | 2.0 | 1.5 | |

| 140+1.1 0 | 8.0+1.0 0 | 2.8 | 1.6 | 2.5 | |

| 160+1.2 0 | 10.0+1.1 0 | 3.2 | 1.6 | 2.5 | |

| 200+1.3 0 | 11.0+1.2 0 | 4.0 | 1.6 | 2.5 | |

| 225+1.4 0 | 11.5+2.4 0 | 4.5 | 1.6 | 2.5 | |

| 250+1.4 0 | 12.0+1.3 0 | 5.0 | 1.6 | 3.5 | |

| 280+1.5 0 | 12.5+2.6 0 | 5.6 | 1.6 | 3.5 | |

| 315+1.6 0 | 13.0+1.4 0 | 6.3 | 1.25 | 3.5 | |

| 355+1.6 0 | 14.0+2.8 0 | 7.1 | 1.25 | 3.5 | |

| 400+1.6 0 | 15.0+1.5 0 | 8.0 | 1.25 | 3.5 | |

| 500+1.7 0 | 16.0+1.6 0 | 10.0 | 1.0 | 4.0 | |

| 630+1.8 0 | 17.0+1.7 0 | 12.3 | 1.0 | 4.0 | |

| Qaphela: Uxinzelelo oluncinci lombhobho odibeneyo luxinzelelo oluphezulu oluvunyelwe ukuba umbhobho uthuthe amanzi kwi-20 ° С. Ukuba iqondo lokushisa liyatshintsha, uxinzelelo olusebenzayo kufuneka lulungiswe ngokwe-coefficient yoxinzelelo lobushushu bezinto ezahlukeneyo. Ixabiso le-S: umgama ukusuka kububanzi bangaphandle bokuqiniswa ukuya kwindawo yangaphandle yombhobho. | |||||

| Iimfuno zokusebenza komzimba kunye noomatshini | ||

| Iprojekthi | Ukusebenza | |

| Ukuqina kweringi, KN/m2 | >8 | |

| Uvavanyo olucaba | Ayophukanga | |

| Ukuncipha kwexesha elide (100 ° С, gcina i-1h) | <0.3% | |

| Uvavanyo lwe-hydraulic | Ubushushu: 20 ° С; Ixesha: 1h; Uxinzelelo lwegama x2 | Ayophukanga |

| Ubushushu: 80 ° С; Ixesha: 165h; Uxinzelelo: Uxinzelelo lwegama x2x0.71 (into yokunciphisa) | ||

| Uvavanyo loxinzelelo lwe-Burst | Ubushushu: 20 ° С, ukuqhuma uxinzelelo ≥ uxinzelelo lwegama x3.0 | Ukuqhushumba |

| Ixesha lokungeniswa kwe-oxidation (200 ° С), min | ≥20 | |

| *Ukumelana nemozulu* Ukwamkelwa okongezelekayo kwemibhobho≥3.5J/m2 Emva kokuguga kwamandla | Uvavanyo lwe-Hydraulic, iimeko zokulinga ziyafana nenqaku le-3 kule theyibhile | Ayophukanga |

| Uvavanyo loxinzelelo lwe-Burst, iimeko zokuvavanya zifana nento ye-4 kule tafile | Hayi ukuqhushumba | |

| Ixesha lokungeniswa kwe-oxidation (200 ° С), min | ≥10 | |

*Ngombhobho odityanisiweyo oluhlaza kuphela*